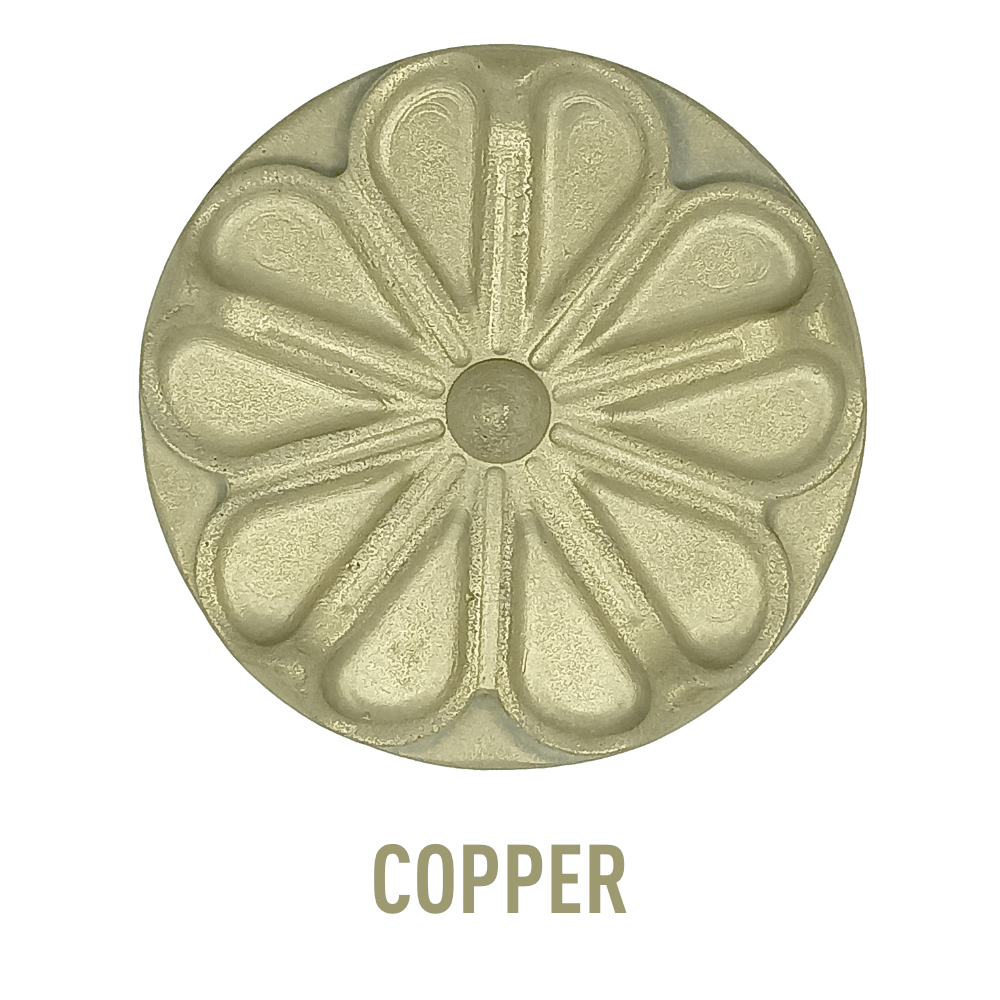

Jesmonite AC 730 Flex Metal - Copper

Product Description

Jesmonite Flex Metal Gel Coats are a revolutionary new material that allows you to achieve the look and feel of real metal in a durable and versatile water-based acrylic resin coating. These gel coats are formulated using real metal powder, which gives them an accurate replica of metal, making it perfect for architectural and design projects that require a premium finish.

One of the most impressive features of Jesmonite Flex Metal Gel Coats is their versatility. They can be used on a wide range of substrates, including wood, plaster and metal. They can also be shaped and molded into various forms and is suitable for indoor and outdoor use. The material can be polished to reveal the metal powders and finished to mimic the appearance of real metal, and also achieve a fire rating of B-s1-d0 and fully compatible with Jesmonite AC730 and AC830, making them an ideal choice for cladding panels, architectural elements, sculpture, tableware, furniture, water features, lighting elements and decorative tiles.

How to Use?

Application:

1. Jesmonite Flex Metal Gel Coats can be applied using a brush, to a thickness of 1mm-2mm.

2. Brush must be kept stirred whilst applying to stop any settlement of the heavy metal powders contained within the material.

_

Backing Material:

1. Jesmonite Flex Metal Gel Coats are used in combination with AC730 or AC830 as a backing material mixed with either Flex or standard liquids depending upon the type of object being manufactured.

-

Premix and Laminating:

1. Flex Metal Gel Coats can be backed up by casting into the mould, or by premixing and laminating.

2. Chopped strands can be added to create a premix for improved strength in cast panels.

3.Laminating with Quadaxial Glass Reinforcement can also be used to optimize strength to weight ratio.

_

Colors:

Flex Metal Liquids are compatible with Jesmonite paste pigments. Pigments should be added to the weighed liquids and mixed thoroughly before adding the powders.

_

Polishing:

The Jesmonite Flex Metal Gel Coat surface can be polished with fine grades of wire wool and polishing machinery to reveal the metallic powders. This will bring out the metal finish and give it a more realistic look.

_

Patination:

Jesmonite Flex Metal Gel Coats can be patinated, which is a process of applying chemical solutions to the surface of the casted object to change its color and give it an aged or weathered appearance.

_

Sealing:

A sealer can be applied to the surface of the casted object to protect it and enhance the metal finish.

Jesmonite Flex Metal Gel Coats are a revolutionary new material that allows you to achieve the look and feel of real metal in a durable and versatile water-based acrylic resin coating. These gel coats are formulated using real metal powder, which gives them an accurate replica of metal, making it perfect for architectural and design projects that require a premium finish.

One of the most impressive features of Jesmonite Flex Metal Gel Coats is their versatility. They can be used on a wide range of substrates, including wood, plaster and metal. They can also be shaped and molded into various forms and is suitable for indoor and outdoor use. The material can be polished to reveal the metal powders and finished to mimic the appearance of real metal, and also achieve a fire rating of B-s1-d0 and fully compatible with Jesmonite AC730 and AC830, making them an ideal choice for cladding panels, architectural elements, sculpture, tableware, furniture, water features, lighting elements and decorative tiles.

Application:

1. Jesmonite Flex Metal Gel Coats can be applied using a brush, to a thickness of 1mm-2mm.

2. Brush must be kept stirred whilst applying to stop any settlement of the heavy metal powders contained within the material.

_

Backing Material:

1. Jesmonite Flex Metal Gel Coats are used in combination with AC730 or AC830 as a backing material mixed with either Flex or standard liquids depending upon the type of object being manufactured.

-

Premix and Laminating:

1. Flex Metal Gel Coats can be backed up by casting into the mould, or by premixing and laminating.

2. Chopped strands can be added to create a premix for improved strength in cast panels.

3.Laminating with Quadaxial Glass Reinforcement can also be used to optimize strength to weight ratio.

_

Colors:

Flex Metal Liquids are compatible with Jesmonite paste pigments. Pigments should be added to the weighed liquids and mixed thoroughly before adding the powders.

_

Polishing:

The Jesmonite Flex Metal Gel Coat surface can be polished with fine grades of wire wool and polishing machinery to reveal the metallic powders. This will bring out the metal finish and give it a more realistic look.

_

Patination:

Jesmonite Flex Metal Gel Coats can be patinated, which is a process of applying chemical solutions to the surface of the casted object to change its color and give it an aged or weathered appearance.

_

Sealing:

A sealer can be applied to the surface of the casted object to protect it and enhance the metal finish.

AUTHENTIC

The use of real metal powder in the formulation of Jesmonite Flex Metal Gel Coats gives the material an authentic and realistic metal finish.

UNLEASH THE BEAUTY OF METAL

Creating a Unique Look with Jesmonite Flex Metal Gel Coats in Copper Finish

Jesmonite: A Trusted and Sustainable Choice Since 1980

Jesmonite is a range of eco-friendly materials used by artists, manufacturers, and architects for a variety of applications. The company was founded in the 1980s by Peter Hawkin, and their most popular product, AC100, is still sold worldwide today.

Jesmonite materials are water-based and use ingredients sourced through local supply chains to minimize CO2 emissions and carbon footprint. The company is committed to supplying eco-friendly products and achieving carbon neutral status.

Jesmonite is known for its versatility and ability to replicate a wide range of textures and fine details. It can be used to create anything from jewelry to coasters to table tops, and offers a range of colors, textures, and finishes.

Jesmonite is a go-to material for artists worldwide due to its environmentally friendly resin and endless design potential.

FAQs

Frequently asked questions about Haksons Opaque Pigments

What are Jesmonite Flex Metal Gel Coats?

Jesmonite Flex Metal Gel Coats are formulated to produce metal finishes that are both decorative and durable. They are available in four finishes: Bronze, Copper, Brass, and Silver Bronze and are used in combination with AC730 or AC830 as a backing material mixed with either Flex or standard liquids depending on the type of object being manufactured.

How should Jesmonite Flex Metal Gel Coats be mixed and used?

Jesmonite Flex Metal Gel Coats should be mixed using a High-shear Mixing Blade and must be used with accurate scales and a Jesmonite High-shear Mixing Blade to ensure that the compound performs within its specification. The mixture can be adjusted to suit the application or the needs of the end user. Flex Metal Gel Coats work best using Silicon Rubber moulds, but it is also possible to use Polyurethane moulding compounds with an appropriate spray release wax.

How can I achieve a surface finish with Jesmonite Flex Metal Gel Coats?

Jesmonite Flex Metal Gel Coats are formulated to produce a metal finish. The finish can be achieved using a variety of polishing media, such as '000' or fine grade steel wool. The surface should then be polished using a clean dry cotton cloth. It is also possible to apply a hard clear wax for internal use, or to seal the piece using Jesmonite Gloss Stone Guard Sealer. Many different colors and patinas can be achieved using cold patinating solutions.

How do I properly cure Jesmonite Flex Metal Gel Coats?

Objects should be kept in a warm, but not overly dry environment during the curing period. They should be racked to allow optimum air-flow, and stored in such a way that panels cannot ‘creep’ or bow under their own weight. To accelerate final strengths casts can be placed in a warm room at around 40oC. Finished products should be packaged only when cured. Care should also be taken when using plastic packaging, particularly in damp storage areas, as this can lead to surface staining and possible water marking.

How do I clean up after using Jesmonite Flex Metal Gel Coats?

Because Jesmonite is water-based, its easy to clean up when you have finished. Scrape any excess unused Jesmonite into the bin then wash your hands, mixing pots, brushes, and the mould in warm soapy water. It’s that easy! You can use White Spirit to remove any pigment residue from your mould if necessary.