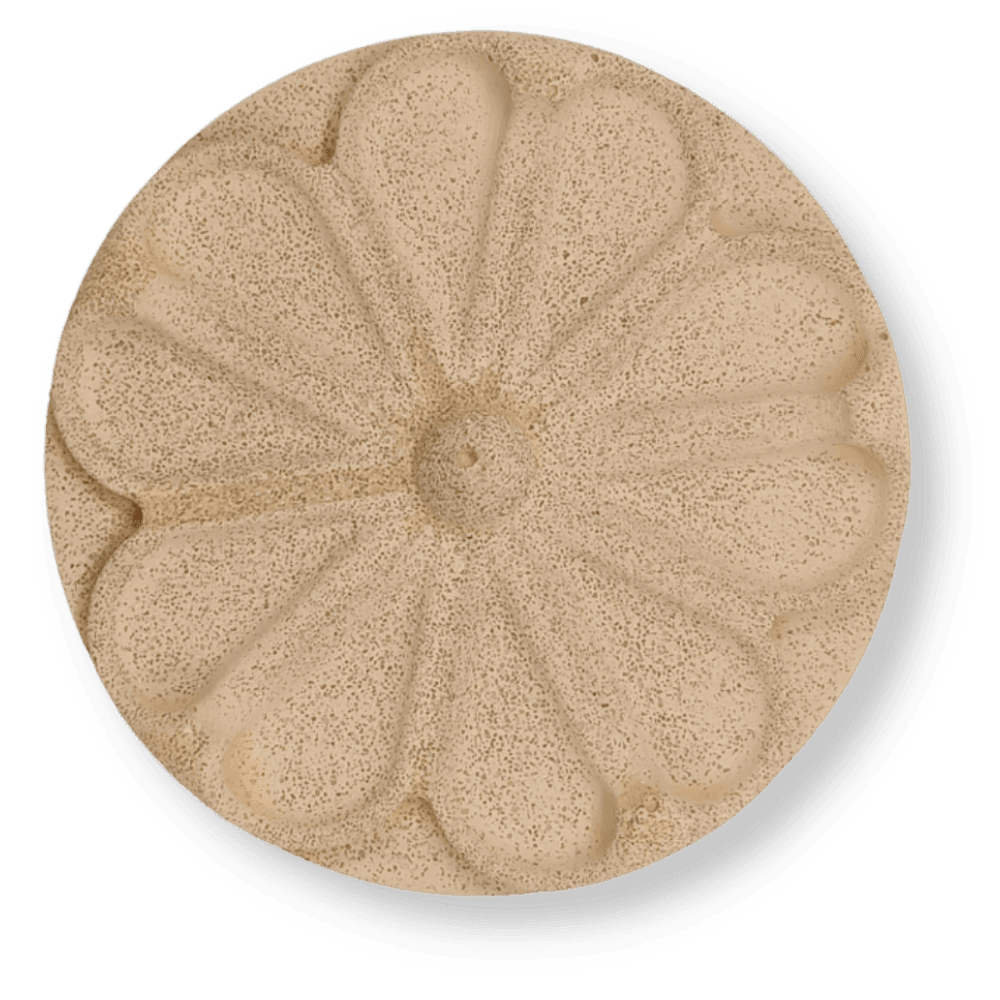

Jesmonite AC 730 - Old Terracotta

Product Description

Jesmonite AC730 is a highly versatile material that is suitable for a wide range of applications. In addition to its ability to mimic the appearance of natural materials such as stone or wood, AC730 can also be used for decorative cladding, art installations, and a variety of other creative projects. Its durability and water-resistant properties make it ideal for use in both indoor and outdoor settings, and its long cure time ensures that it will hold up to wear and tear over time. So whether you are a small business owner looking to create unique home decor pieces or an artist seeking new materials to explore, Jesmonite AC730 is an excellent choice for a wide array of applications.

How to Use?

Step 1: Begin by preparing your surface. Make sure it is clean, dry, and free of any debris or contaminants.

Step 2: Next, mix the Jesmonite AC730 according to the manufacturer's instructions. The mixing ratio for this product is typically 2.5 parts Jesmonite AC730 base to 1 part Jesmonite AC730 liquid.

Step 3: Once the Jesmonite AC730 is fully mixed, you can add any desired pigments or coloring agents to achieve the desired stone finish.

Step 4: Apply the Jesmonite AC730 to your surface using a trowel or spatula, working it into the desired shape and texture.

Step 5: Allow the Jesmonite AC730 to cure for 3 to 4 hours, or according to the manufacturer's instructions.

Step 6: Once the Jesmonite AC730 has cured, you can optionally acid etch the surface to achieve a more authentic stone finish. To do this, simply apply a small amount of acid to the surface and allow it to sit for a few minutes before rinsing it off.

Step 7: Finally, to protect your stone finish, you may want to apply a sealant. Choose a sealant that is suitable for use with Jesmonite AC730 and follow the manufacturer's instructions for application.

Jesmonite AC730 is a highly versatile material that is suitable for a wide range of applications. In addition to its ability to mimic the appearance of natural materials such as stone or wood, AC730 can also be used for decorative cladding, art installations, and a variety of other creative projects. Its durability and water-resistant properties make it ideal for use in both indoor and outdoor settings, and its long cure time ensures that it will hold up to wear and tear over time. So whether you are a small business owner looking to create unique home decor pieces or an artist seeking new materials to explore, Jesmonite AC730 is an excellent choice for a wide array of applications.

Step 1: Begin by preparing your surface. Make sure it is clean, dry, and free of any debris or contaminants.

Step 2: Next, mix the Jesmonite AC730 according to the manufacturer's instructions. The mixing ratio for this product is typically 2.5 parts Jesmonite AC730 base to 1 part Jesmonite AC730 liquid.

Step 3: Once the Jesmonite AC730 is fully mixed, you can add any desired pigments or coloring agents to achieve the desired stone finish.

Step 4: Apply the Jesmonite AC730 to your surface using a trowel or spatula, working it into the desired shape and texture.

Step 5: Allow the Jesmonite AC730 to cure for 3 to 4 hours, or according to the manufacturer's instructions.

Step 6: Once the Jesmonite AC730 has cured, you can optionally acid etch the surface to achieve a more authentic stone finish. To do this, simply apply a small amount of acid to the surface and allow it to sit for a few minutes before rinsing it off.

Step 7: Finally, to protect your stone finish, you may want to apply a sealant. Choose a sealant that is suitable for use with Jesmonite AC730 and follow the manufacturer's instructions for application.

DYNAMIC

Experience the versatility and dynamic capabilities of Jesmonite AC730 in your next project

Jesmonite: A Trusted and Sustainable Choice Since 1980

Jesmonite is a range of eco-friendly materials used by artists, manufacturers, and architects for a variety of applications. The company was founded in the 1980s by Peter Hawkin, and their most popular product, AC100, is still sold worldwide today.

Jesmonite materials are water-based and use ingredients sourced through local supply chains to minimize CO2 emissions and carbon footprint. The company is committed to supplying eco-friendly products and achieving carbon neutral status.

Jesmonite is known for its versatility and ability to replicate a wide range of textures and fine details. It can be used to create anything from jewelry to coasters to table tops, and offers a range of colors, textures, and finishes.

Jesmonite is a go-to material for artists worldwide due to its environmentally friendly resin and endless design potential.

"Effortlessly achieve a range of finishes and effects with this versatile and durable composite. The ideal choice for creative projects and professional-grade results."

The Ultimate Stone Finish

- Versatility:

AC730 is a versatile material that can be used in a wide range of applications and is suitable for use in both indoor and outdoor projects. It is also easy to work with and can be molded, shaped, and sculpted to achieve a range of finishes and effects.

- Durability:

AC730 is a highly durable material that is resistant to water, UV radiation, and wear and tear. This makes it ideal for use in projects that will be exposed to the elements or subjected to heavy use.

- Ease of use:

AC730 is easy to work with and can be molded, shaped, and sculpted to achieve a wide range of finishes and effects. It is also easy to mix and apply, making it suitable for use by both professionals and hobbyists.

- Low environmental impact:

AC730 is a non-toxic, low-VOC material that is safe for use in both indoor and outdoor projects. It is also fully recyclable, making it an environmentally friendly choice for your projects.

| Feature | Jesmonite AC730 | Regular GRC |

|---|---|---|

| Cure Time | 3-4 hours | 24 hours |

| Ease of Use | High | Poor |

| Curing Type | Chemical | Hydration |

| Durability | High | Moderate |

| Water Resistance | High | Moderate |

- Versatility:

AC730 is a versatile material that can be used in a wide range of applications and is suitable for use in both indoor and outdoor projects. It is also easy to work with and can be molded, shaped, and sculpted to achieve a range of finishes and effects.

- Durability:

AC730 is a highly durable material that is resistant to water, UV radiation, and wear and tear. This makes it ideal for use in projects that will be exposed to the elements or subjected to heavy use.

- Ease of use:

AC730 is easy to work with and can be molded, shaped, and sculpted to achieve a wide range of finishes and effects. It is also easy to mix and apply, making it suitable for use by both professionals and hobbyists.

- Low environmental impact:

AC730 is a non-toxic, low-VOC material that is safe for use in both indoor and outdoor projects. It is also fully recyclable, making it an environmentally friendly choice for your projects.

| Feature | Jesmonite AC730 | Regular GRC |

|---|---|---|

| Cure Time | 3-4 hours | 24 hours |

| Ease of Use | High | Poor |

| Curing Type | Chemical | Hydration |

| Durability | High | Moderate |

| Water Resistance | High | Moderate |

Enhance your projects with Haksons Resin and Pigments

Add vibrancy and durability to your Jesmonite creations

FAQs

Frequently asked questions about Haksons Opaque Pigments

Jesmonite Quantity Calculator

What is Jesmonite AC730 used for?

Jesmonite AC730 is a water-based acrylic liquid and blended base that is formulated for external use. It is used to create small castings and is primarily designed as a laminating compound for use with suitable glass fibre reinforcements.

What are the mixing instructions for Jesmonite AC730?

To mix Jesmonite AC730, use accurate scales and a Jesmonite High-shear Mixing Blade. Mix the liquids and base in separate clean containers at a ratio of 1:5. Use a drill with variable speed control on the trigger to slowly add the base to the liquids while mixing continuously at low speed. Increase the mix speed to around 1,000rpm and mix for an additional 60 seconds or until the mix is smooth, flowing, and free from lumps.

How can I extend the pot-life of the mixed material?

Retarder can be added to the pre-weighed liquids to extend the pot-life of the mixed material. Typical inclusion rates are 2g-8g, but a small test is recommended as the precise timing is dependent on both temperature and mix size.

How can I add strength to casts made with Jesmonite AC730?

To add strength to casts made with Jesmonite AC730, 13mm Coarse Chopped Strands can be added to create a premix. A 1mm-2mm Gel Coat can also be applied to the face of the mould to stop the glass reinforcements showing on the face of the cast.

How long does Jesmonite AC730 take to cure?

Jesmonite AC730 achieves over 90% of its ultimate strength in the first 24 hours. Both cast and laminated objects should be kept in a warm, dry environment during this period.

How should I store and package finished products made with Jesmonite AC730?

Finished products should be racked to allow optimum air-flow and stored in such a way that panels cannot ‘creep’ or bow under their own weight. They should be packaged only when cured, and care should be taken when using plastic packaging, particularly in damp storage areas, as this can lead to surface staining and possible water marking.